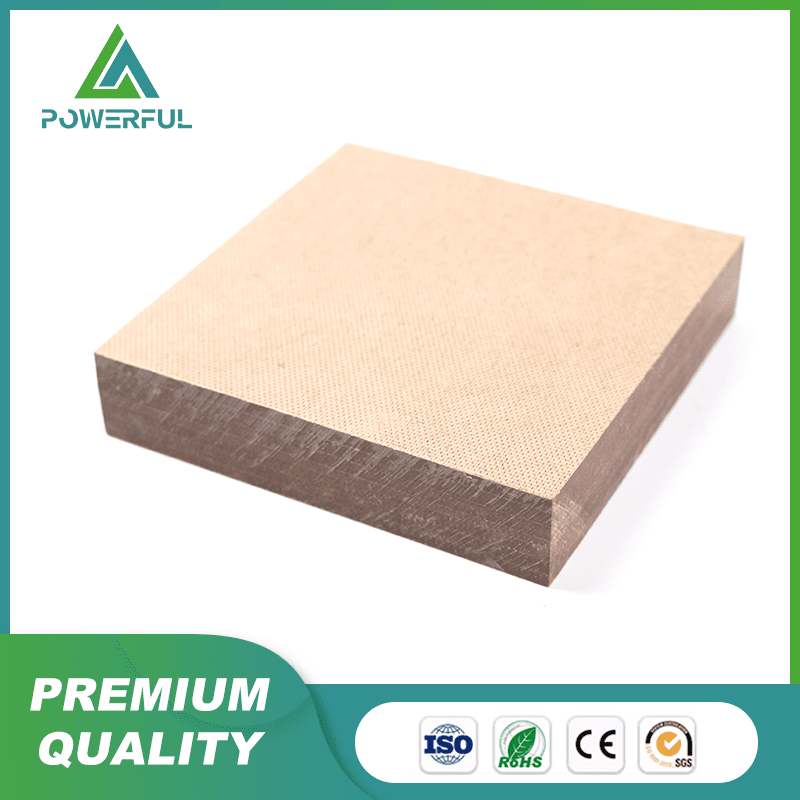

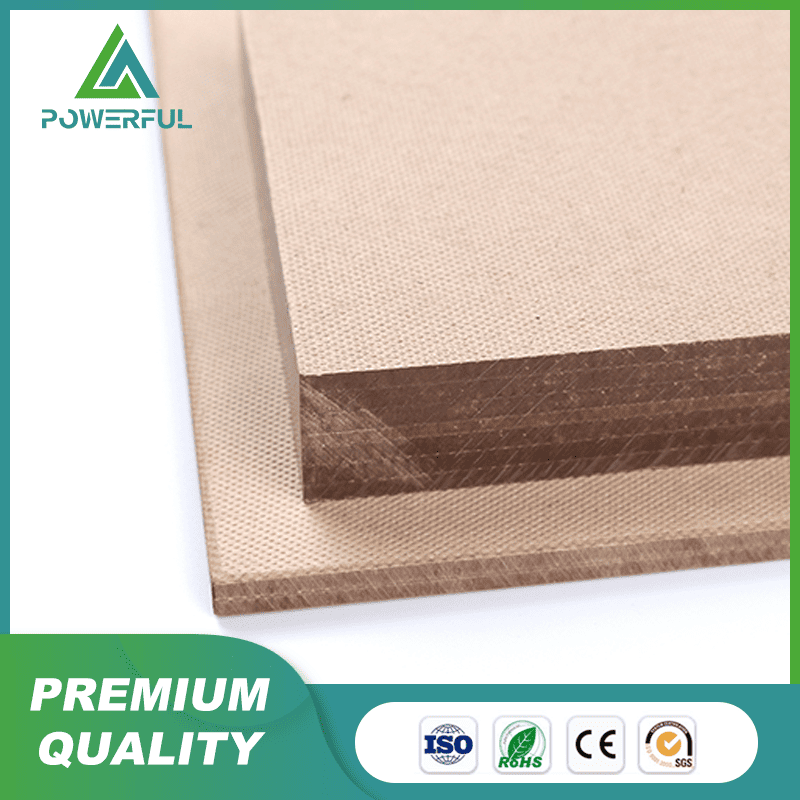

Laminating of hot-press-dried Transformerboard PSP3052 will result in a higher thickness than 4.0 mm.

The range of thickness of laminated Transformerboard begins from 5.0 mm up to 120.0 mm.

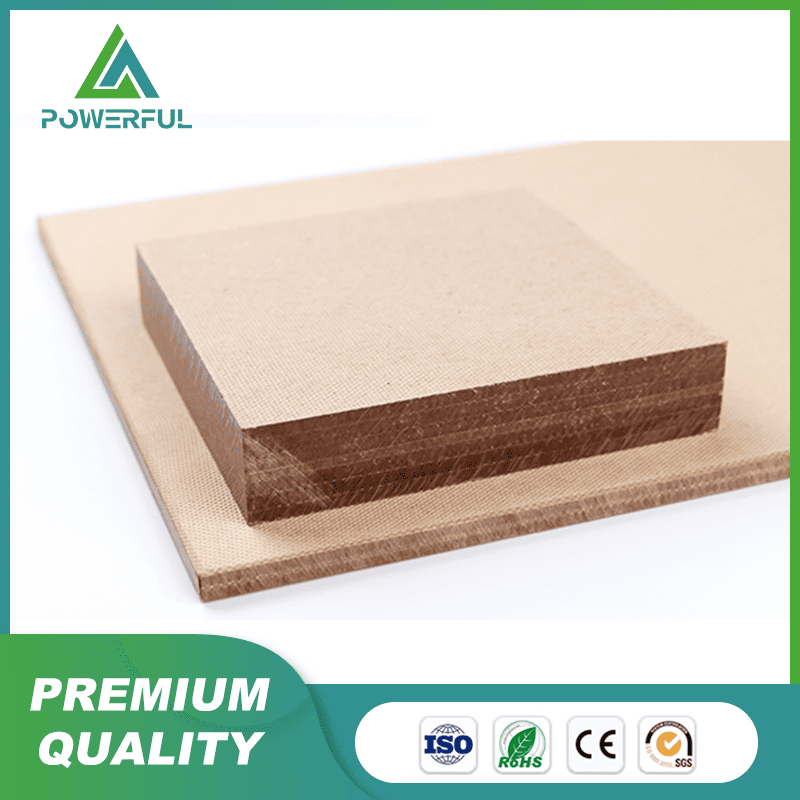

Features

Highest mechanical strength

Excellent electrical insulation properties

Stable dimension

Applications

Typical applications of laminated TRANSFORMERBOARD are pressure rings, static rings, beams, clamping plates and support strips etc. in power, distribution and special transformers.

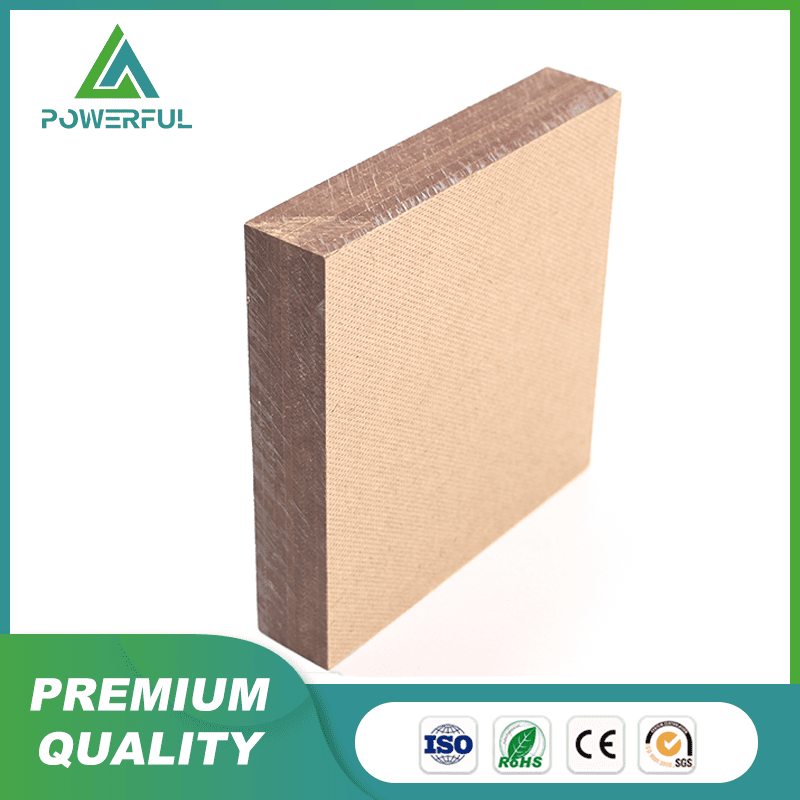

Technical Data

Property | Unit | Standard | Testing Result |

Thickness Tolerance | % | ±7.5 | -0.8 |

Apparent density | g/cm3 | 1.15-1.30 | 1.28 |

Shrinkage MD CMD Thickness | % |

≤0.50 ≤0.70 ≤6.00 |

0.48 0.67 5.80 |

Ash content | % | ≤1.0 | 0.52 |

PH of aqueous extract | % | 6-9 | 7.40 |

Oil absorption | % | ≥6.0 | 8.50 |

Conductivity of aqueous extract | Ms/m | ≤15.0 | 7.50 |

Electrical strength in oil | KV/mm | ≥8.0 | 12.20 |

Moisture content | % | 5.0-9.0 | 7.20 |

This Technical Data is for size 10.0MM X 2000MM X 1000MM