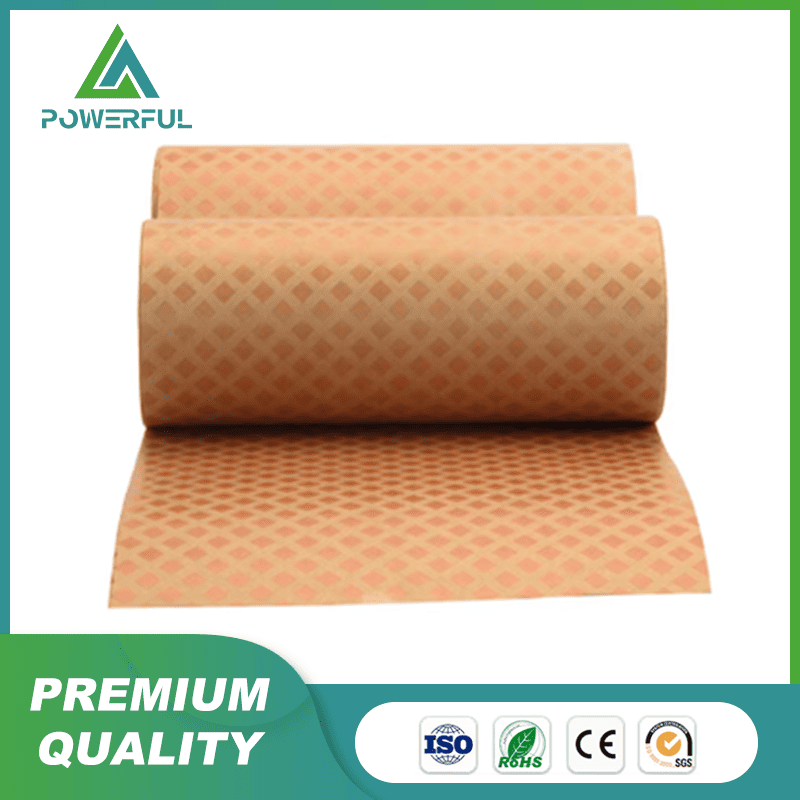

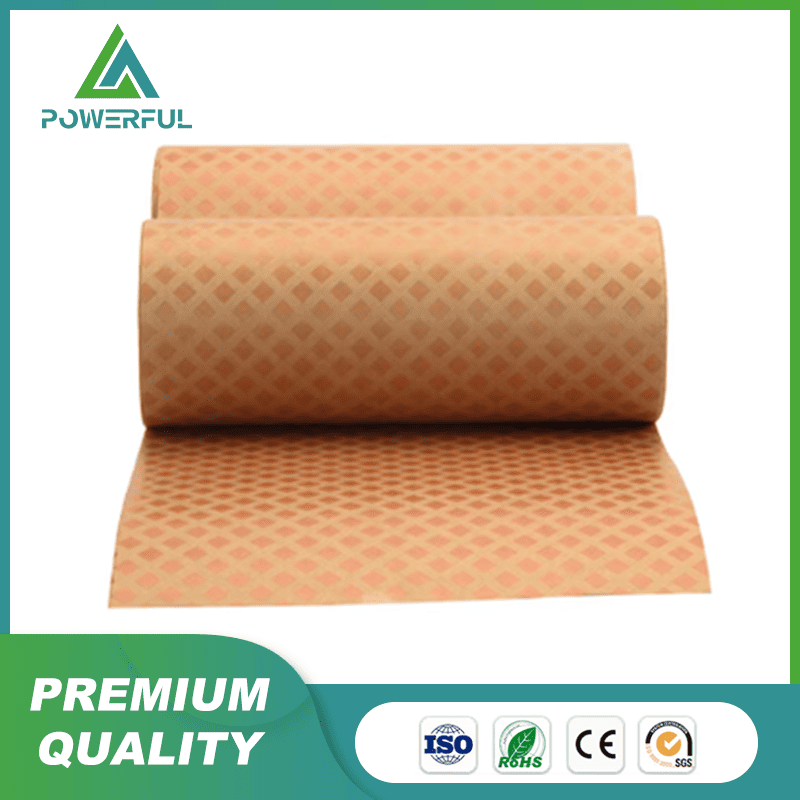

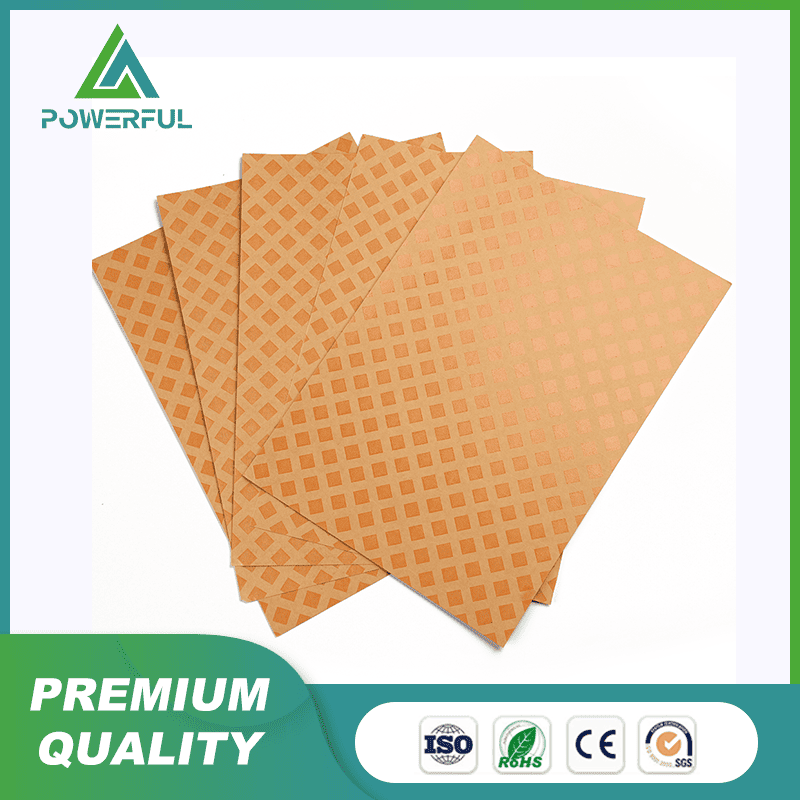

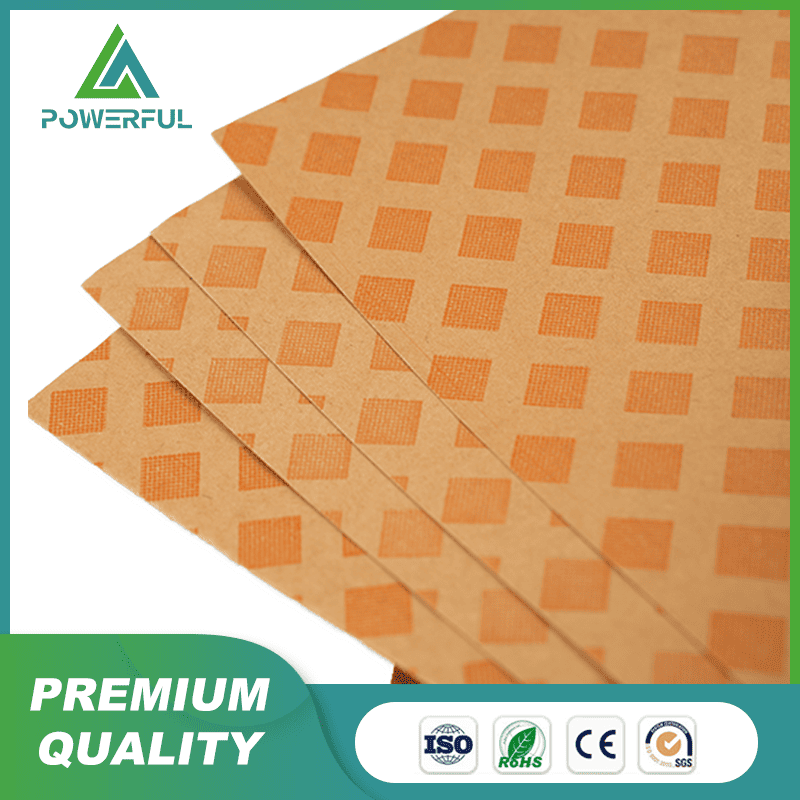

Diamond dotted insulation paper is made of electrical insulating paper coated with heat curable epoxy resin, the epoxy adhesive is applied to both sides of the paper in a diamond pattern consisting of 9.5mm x 9.5mm diamonds with 15.9mm center spacing It is a kind of material with inertia, dry and no conglutination at normal temperature (below 30 degree C). The Diamond Dotted Paper will make the electric conductor forever felt up as a hard unit under the high temperature by its internal latency substance. when the temperature is rising up to 90 degree C. The Diamond Paper begins one-off thaw and then one-off solidification .When to keep the temperature at 90 degree C for 90 minutes, the epoxy resin would paste on neighboring cable and paper safely. The felt intensity is as high as to 70psi at 100 degree C (The value at least is equal to 0.275Mpa, America standard)

Features

· Insulation class A (105 °C) according to according to IEC 641

· Kraft paper, 100% sulphate pulp

· High purity and mechanical strength

· Color natural

· Baked enamel coating: Epoxy resin , rhombic, one or both sides

· Good compatibility with liquid dielectic after the baked enamel coating has hardened.

· Care should be taken that the that the layers to be baked remain closely pressed against each other during baking time

Applications

It is to be used in oil-immersed transformers for the insulation between of coils .On the insulation layer, there is a layer dotted epoxy resin that will be changed with high temperature change that is to be called as felt

Available

Thickness: 0.05mm – 0.35mm

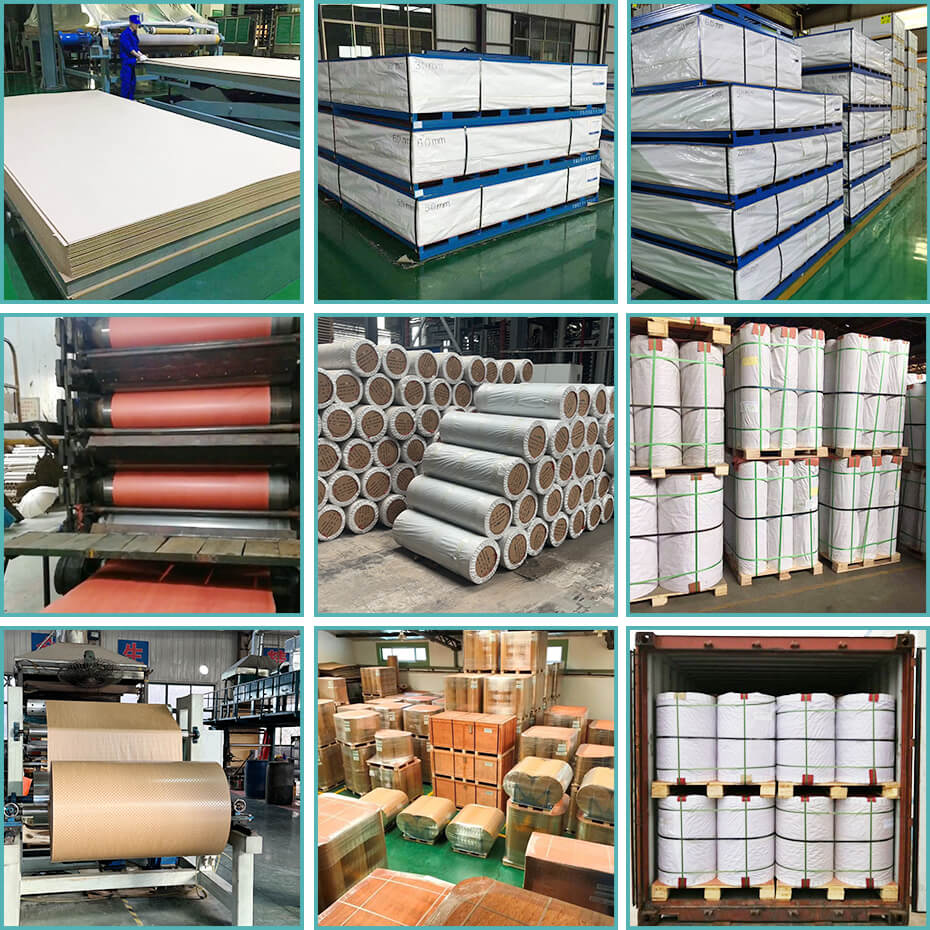

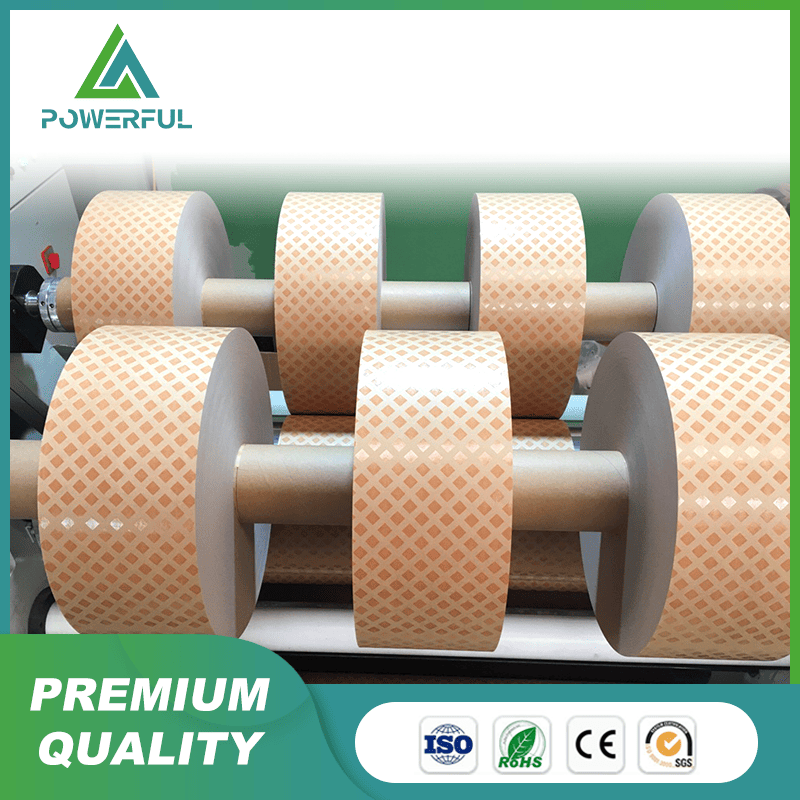

Both in roll and sheet are available

Width: 650mm – 1350mm

Technical Data

Typical properties of Diamond Dotted Paper | ||

Specified Properties | Units | Standard |

Thickness Tolerance | Mm | 0.075, 0.08, 0.13, 0.18, 0.20,0.25, 0.30, 0.35 |

Density | g/mm^3 | 0.95 – 1.15 |

Tensile strength Min | N/mm^2 | MD 70 – 90 |

Elongation Min | % | MD 2.0 – 3.0 |

Breakdown volume Min | KV/mm | In air 11-12 |

Oil Absorption Min | % | 8 |

Moisture Content | % | 4.0-8.0 |

Resin’s Content Min | % | 7 , 6 , 5 , 4 , 3.5 |

Ash Content Max | % | 1.0 |

Adhesion Strength Min | kPa | 450 |

dp | 1000 | |