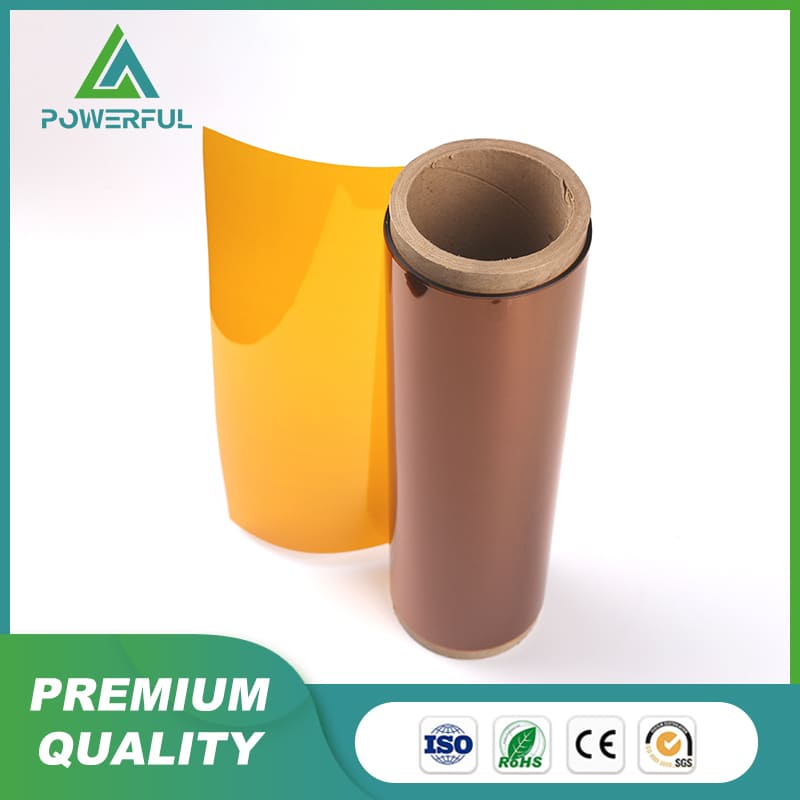

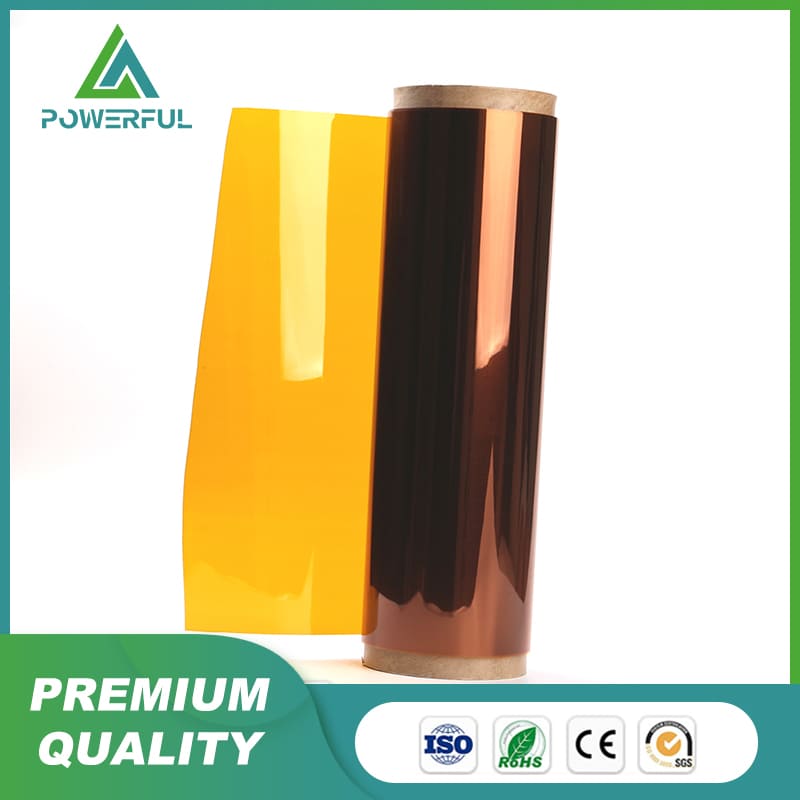

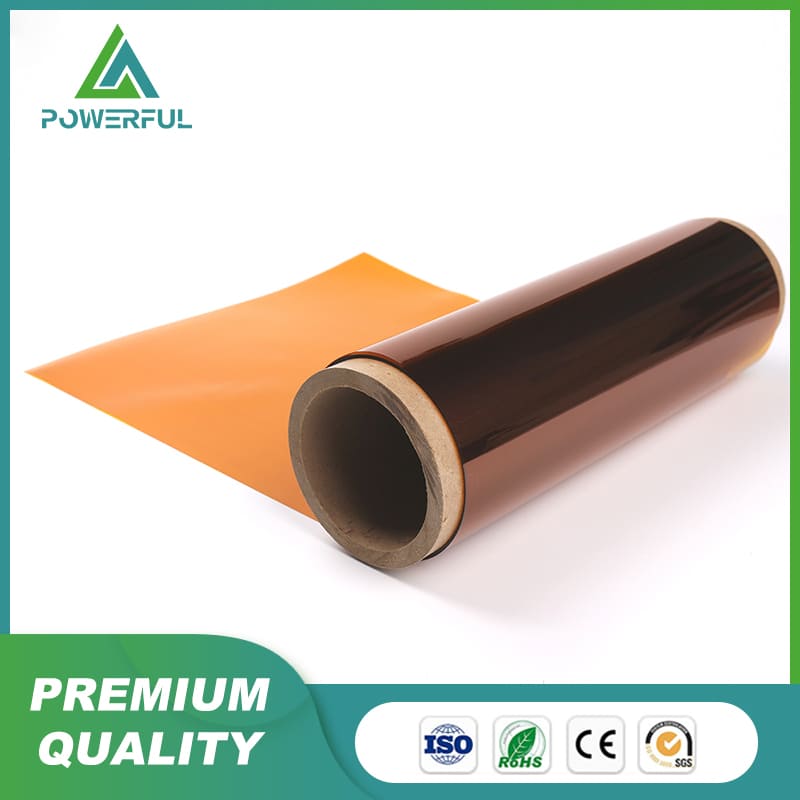

Polyimide Film is synthesized by the polycondensation of aromatic dianhydride and aromatic diamine (PMDA and ODA ). It shows outstanding physical , thermal, electrical, and chemical properties over a wide range of temperature as low as -452F(-269C) and as high as 500F(+260C).It also offers good dimensional stability and can be die-cut, laminated, metallized, formed, thermoformed or adhesive coated.

Features

Operating temperatures: Class H (180’C)

Unique combination of electrical, thermal, chemical and mechanical properties

Applications

It's extensively used in electrical insulation, flexible printed circuits, bar code labels, pressure sensitive tape and safety applications

Available

Thickness: (um/mil)

7.6/0.3, 10.2/0.4, 12.7/0.5, 15/0.6, 19.1/0.75, 25.4/1.0, 50.8/2.0, 76.2/3.0

Width: 260mm, 520mm, 620mm

Length: 500m, 750m, 1000m, 1500m, 3000m

Any special size is available on request

Technical Data

| Density : | 1.42+/-0.02 g/cm3 |

| Tensile Strength : | 135 MPa (MD), 115 MPa (TD) |

| Elongation : | 0.35 |

| Shrinkage : | 1.0 % (150℃), 3.0 % (400C) |

| Breakdown Strength : | 150 MV/m (50HZ) |

| Surface Resistivity : | 1.0x10e13 Ω (200C) |

| Volume Resistivity : | 1.0x10e10 Ω (200C) |

| Dielectric Constant : | 3.5+/-0.4 (50HZ) |

| Loss Tangent : | 4.0x10e-3 (48~62HZ) |